SOLVING ONE OF THE BIGGEST PROBLEMS IN FOOD INDUSTRY

PATHOGENIC DEPOSIT ON FOOD

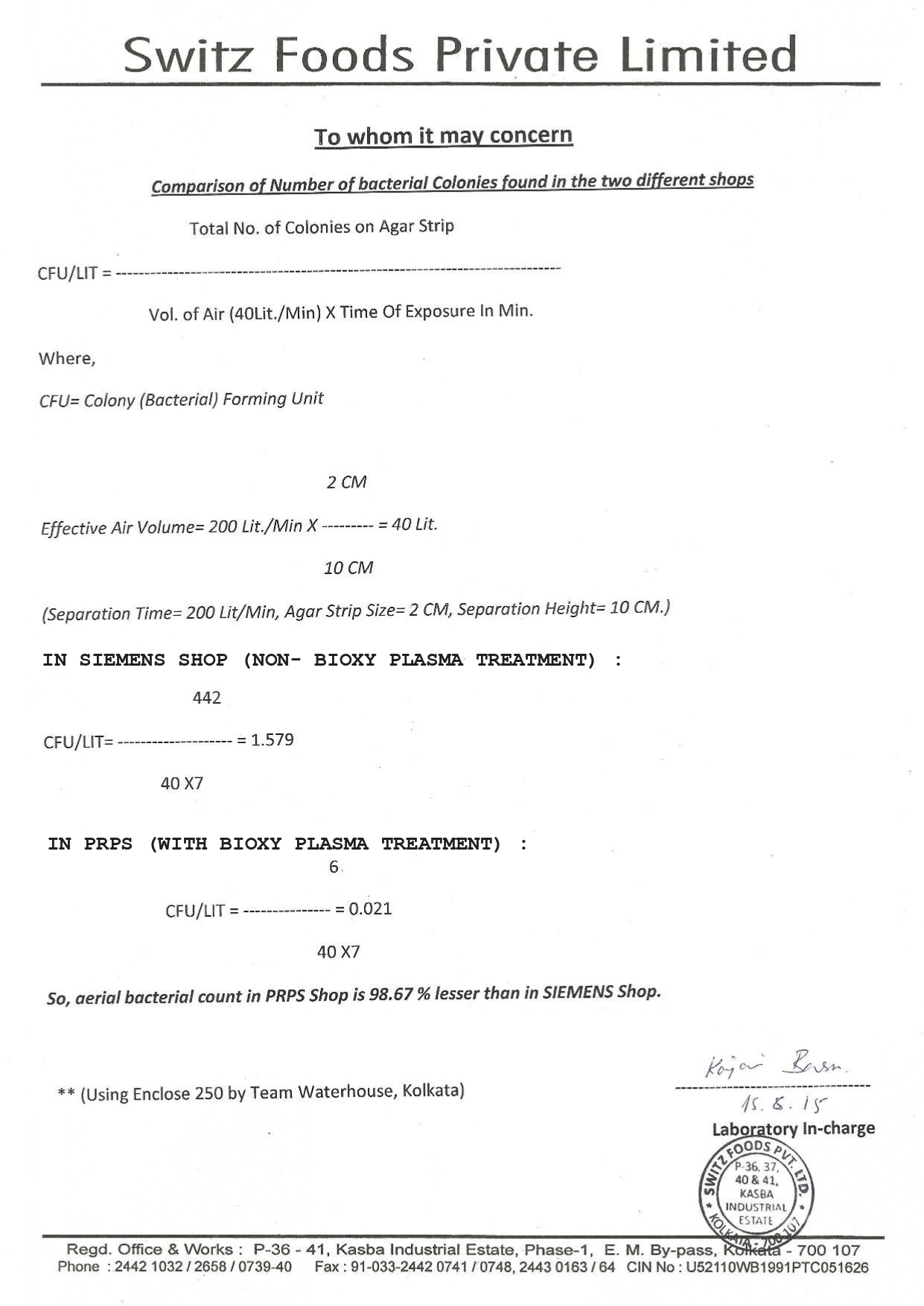

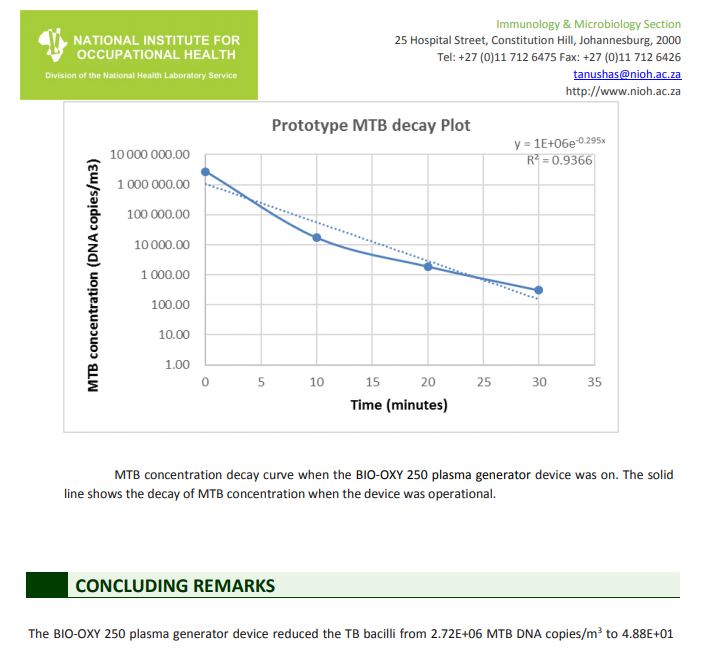

In food factories, notably in Bakery, there is continuous fluctuation of temperature, humidity, etc - as a normal part of manufacturing process. Seasonal changes also affect this obviously. Plus, due to other obvious factors known to food professionals, it leads to growth and multiplication of several infection species, which float in the air inside the food processing area, and then deposit on the surface of the food. In this situation, the processing factories lose terrible amounts of food, sometimes termed as 'wastage loss'. According to regulation authorities, there needs to be proper aerial sterilization in the processing areas, and there is no better solution than Bio Oxygen - for highest infection killing efficacy at safest levels.